Ceiling Fan Installation and Usage Tips

Ceiling fan performance and energy savings rely heavily on the proper installation and use of the ceiling fan. Here are a few tips to ensure quality and product performance.

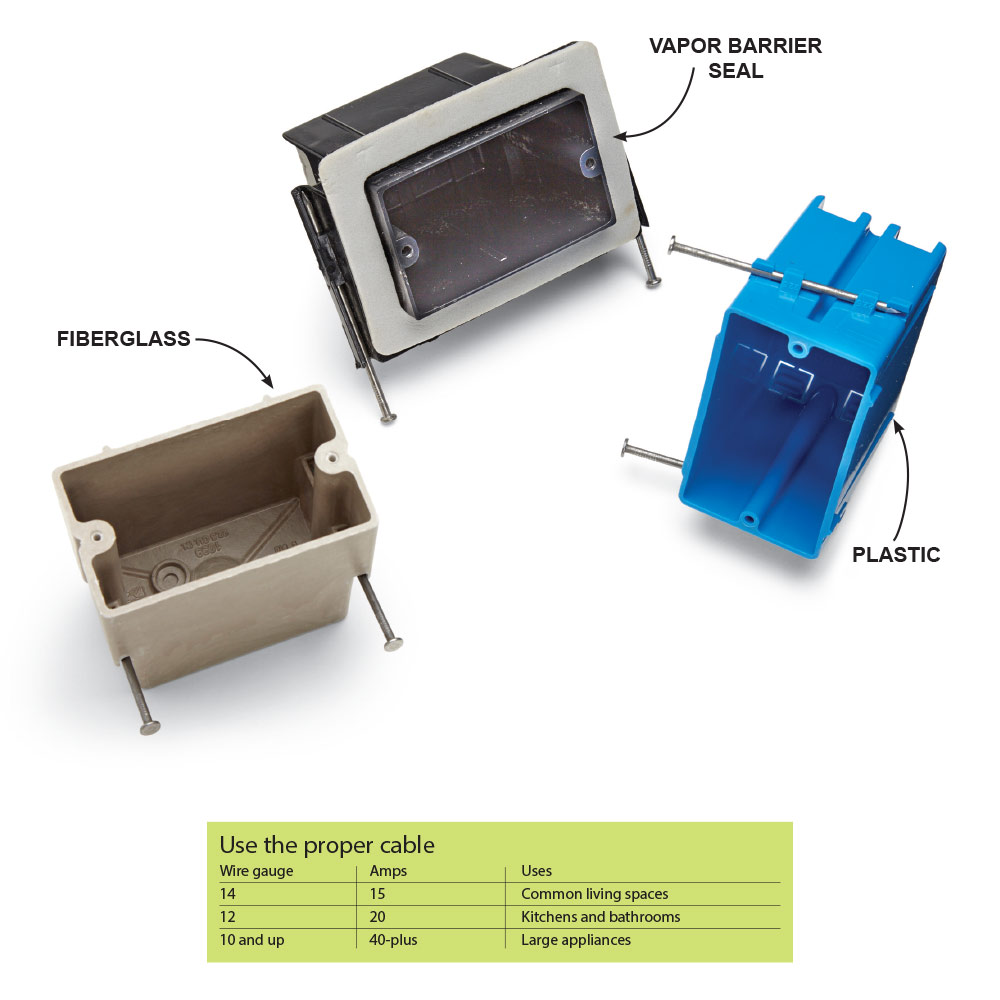

Choosing the Appropriate UL-Rated Electrical Box

Make sure that you use the appropriate UL-listed metal box, marked “For Use With Ceiling Fans.” This outlet box is mounted above the ceiling and also is the point where the fan is attached. This box houses all wiring needed to operate and connect the ceiling fan. If you are replacing a ceiling fixture, most likely you will need to replace the electrical box.

Mounting the Ceiling Fan

If possible, the ceiling fan should be anchored to a ceiling joist. In the case that the joist is not located in the center of the room, a special ceiling fan mounting bracket with spiked ends should be installed between joists. Keep in mind that ceiling fans can weigh as much as 50 pounds!

Balancing a Wobbly Fan

All fan blades should be balanced prior to shipment; however, if the fan is wobbly after installation, there are ways to fix it. First, make sure that all connections are properly aligned and tightly fastened. Check the alignment of the blades by holding a yardstick vertically along the edges; you may be able to gently bend a misaligned blade holder back into proper place. If all blades are aligned, a balancing kit can then be used to pinpoint the culprit. These kits are either provided within product packaging (e.g., balancing clips and blade weights) or can be sent by the manufacturer free of charge. View(link is external) a video with tips on fixing a wobbly fan.

Turn Off When not in the Room

Ceiling fans cool people, not rooms. If the room is unoccupied, turn off the ceiling fan to save energy.

How to Install a Ceiling Fan

Installing a ceiling fan is a good project for the do-it-yourselfer, as you can simply replace a traditional lighting fixture with a fan or fan-and-light kit. You can wire the fan’s light to be controlled by the light switch on the wall and allow the fan to be turned on manually by pulling a cord, install a second switch to control the fan, or purchase a unit operated by remote control.

You’ll need to ensure that the junction box to which you will connect your fan can support its weight (it should say “suitable for fan support”), that you have enough clearance between the fan blades and the ground (at least 7 feet), and that your fan is the appropriate size for your room. For more, see Sizing & Locating a Ceiling Fan.

Remove the old light fixture. (See How to Replace a Light Fixture for information about how to do so.)

Install a ceiling fan mounting bar. If the ceiling box is connected at its center to a bar hanger attached to two joists

If it is not, you will have to install a ceiling fan box with a mounting bar. Take out the old ceiling box, and insert the hanger bar for the mounting box into the ceiling hole. Ram the edges (or “feet”) of the bar toward the two ceiling joists by turning the center of the bar, and use a wrench to tighten the bar and embed the sides into the joists. Attach the ceiling box to the hanger.

Ceiling Fan Frequently Asked Questions

When it comes to ceiling fans I find my clients have a lot of questions, and are unsure about the many types of ceiling fans, installation techniques and what it all means for them. Here I have compiled FAQ’s that I get asked often, as well as some information that you will find informative.

How much do ceiling fans cost to run? A Ceiling Fan is cheap to run at about 2-3 cents per hour. Here’s a great link for calculating any appliance costs in Adelaide Calculate Appliance Running Costs. A Ceiling Fan will also aid in saving cooling costs when used in conjunction with home air conditioners.

What does the Summer/Winter switch do? This switch is found above the motor on the ceiling fan and sometimes labelled S and W. In the Summer position, the fan will blow cooling air down that you can feel. In the Winter position, the fan will turn in reverse. This blows warm air over the ceiling and down the walls.

What does the number of blades mean? The most common are 3, 4 or 5 blade fans. There’s not a lot of difference in air flow. A 5 blade fan has more drag and will require more power to run the fan. A 3 blade fan is usually a metal blade fan designed to push a lot of air for its size and thus can be a little noisy. A 4 blade fan tends to be a good compromise for air flow and efficiency. Very large fans may have more blades due to design and aesthetics.

Metal or Timber Blade Fan? A metal blade fan in most cases will push more air than a timber blade fan due to the blade angle and design. As a result they are a little noisier but work well in living areas and outside areas. A timber blade fan is quieter to run and well suited to sleeping areas, however they do not push as much air as a metal blade fan.

WHICH WAY SHOULD YOUR CEILING FAN SPIN AND OTHER HELPFUL COOLING TIPS

Summer is coming, and we can feel the sweat and see the high electric bills already! One way to lower the cost of running your air conditioning unit is also to use your ceiling fan. Ceiling fans circulate cooled air in a room to make people feel cooler. That means you can increase your thermostat by several degrees without causing a noticeable difference in comfort.

Many people don’t realize that you can save money in the summer by running your ceiling fan in conjunction with your air conditioner. With a ceiling fan running, you can feel about 5 degrees cooler. This means you can turn down your AC and lessen its running load. Before you turn your AC on in the shoulder seasons, try running your fan first and see if you can save even more money by avoiding AC for a couple more weeks or most waking hours. A typical central air conditioning unit uses about 3,500 watts of energy when running, while an average ceiling fan running on high uses only about 60 watts.

Which Direction Should Your Ceiling Fan Spin in Summer?

Most fans have a clockwise and counterclockwise setting, usually controlled by a small button or switch near the fan base. Each direction is appropriate for different seasons. However, because fan blades are also angled, we cannot tell you which direction works for which season, on your specific fan. You’ll have to do a small experiment.

Stand beneath your fan and turn it on. If you immediately feel a breeze, that is the summer setting. If you do not immediately feel a breeze, turn off the fan, and look for the small button to run the fan in the opposite direction. Take this opportunity to dust your fan. It’s often an overlooked task, but removing any particulates from the air in your home helps keep the air quality high while also cutting down on internal cleaning of the air ducts.

Ceiling Fans Keep People Cool, Not Rooms

What do we mean? Unlike a central AC unit that is cooling your home, a fan is creating a cooling effect. Fans will not lower the temperature; they make you feel cooler by circulating the air. A fan is like a gentle breeze, but if you think about it, your furniture doesn’t benefit from that feeling, only you do. That means when you leave a room, turn off the fan to save on your electric bill.

Helpful Tips For Purchasing A Ceiling Fan

That thing hanging from the ceiling that provides a cool breeze is an often overlooked part of most rooms of a house. However, if used correctly it can shave some serious dollars off of your energy bill each month, especially during the spring and summer months. So, when it’s time to purchase a new ceiling fan, we highly recommend spending a bit of time doing some research and finding one that checks off all of the following considerations

Airflow

This may sound obvious, but a ceiling fan that really provides adequate airflow and circulation is a must. What you may not know however, is that a ceiling fan’s airflow is measured in cubic feet per minute and the fan’s maximum airflow will be listed on the box.

Light Combos

Lots of ceiling fans on the market today incorporate some sort of lighting, if that’s something you prefer. While shopping, it’s important to think about the room the ceiling fan will be installed in and determine whether or not you need some extra overhead lighting.

Efficiency

As we mentioned above, a ceiling fan can really help you save on energy bills if you use it correctly, especially if you use it in conjunction with your air conditioning system. With that said, you’ll want to make sure you’re looking at ceiling fans that are Energy Star rated if it comes with a lighting kit, so be on the lookout for the little blue label.

Location

Did you know there are three main types of fans when it comes to the location where it will be installed? If you’re going to be installing the fan outside, you’ll want to look for one that is wet-rated as opposed to a dry-rated fan if it will only be used indoors. If it’s going to be installed somewhere in between or a room of the house with high humidity (like the bathroom or the laundry room), your best best is a damp-rated ceiling fan.